Design & Optimization

Engineering analyses guide the design and optimization of components and systems — from concept development to performance refinement. Parametric studies, sensitivity analyses, and optimization loops are used to evaluate the influence of geometry, material, and load conditions.

Optimization approaches include manual iteration, scripted workflows, and multi-parameter automated simulations — enabling improved durability, reduced weight, and enhanced functionality across diverse applications.

Key Capabilities

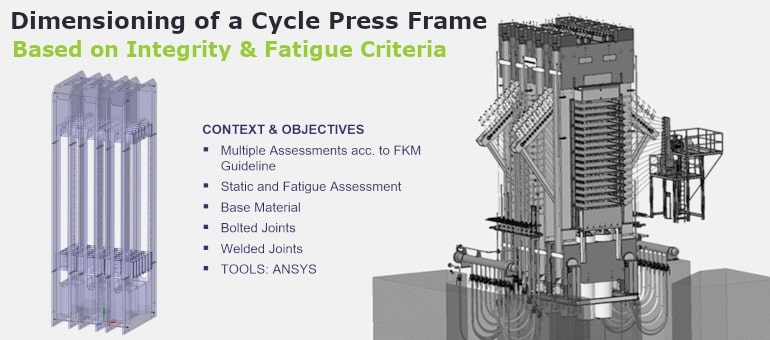

- Design & Code-compliant assessments

- Evaluation of parts, assemblies, joints, and supports

- Topology and shape optimization — for weight reduction and stiffness maximization

- Multi-parameter studies — sensitivity analysis and automated calibration

- Weight-performance trade-off — balancing strength, mass, and manufacturability

- Robustness evaluation — accounting for tolerances, deviations, and load variability

More information

Engineering Expertise, Design and Assessment

Parts, assemblies, bolted and welded joints, sealing systems, and support structures are designed and evaluated — including fatigue, creep, and stress assessments according to relevant standards. Engineering support is provided for interface integration, performance and durability optimization, and alignment with installation and cost targets. Development processes are supported in close collaboration with customer design teams, leveraging experience and know-how gained in international R&D environments.

Example: Design and assessment of a cloth seal-based system at the combustion chamber exit of a gas turbine — ensuring compatibility with existing interfaces and optimizing for performance, durability, installation, and cost. Includes project management and design review support in collaboration with the OEM customer.

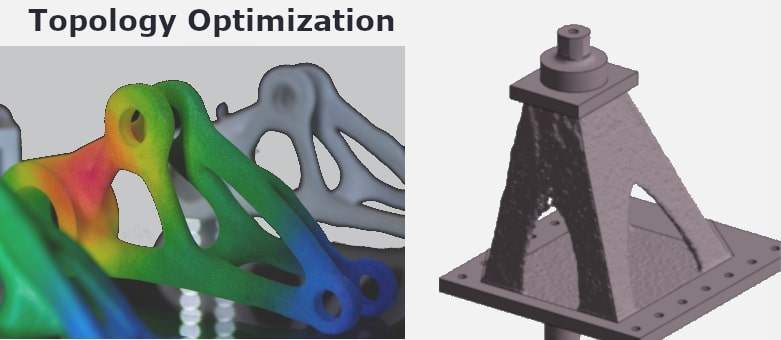

Topology Optimization

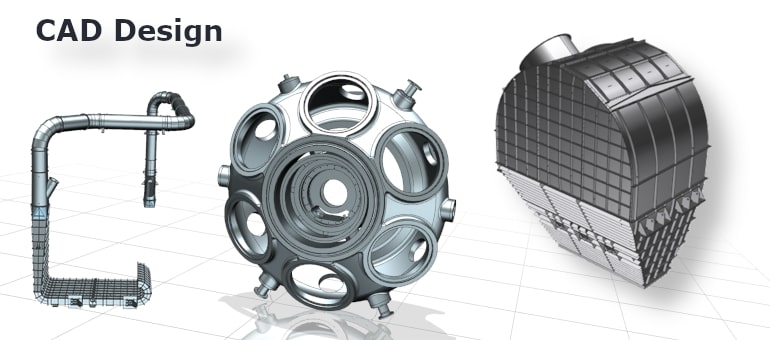

Enables efficient material distribution by identifying optimal structural layouts within a given design space, based on load paths, constraints, and performance targets. This method supports weight reduction, stiffness maximization, and functional integration — often serving as the foundation for additive manufacturing.

Example: Topology optimization of a GT support structure for weight reduction while maintaining stiffness requirements — considering load paths, connection interfaces, and manufacturing constraints.

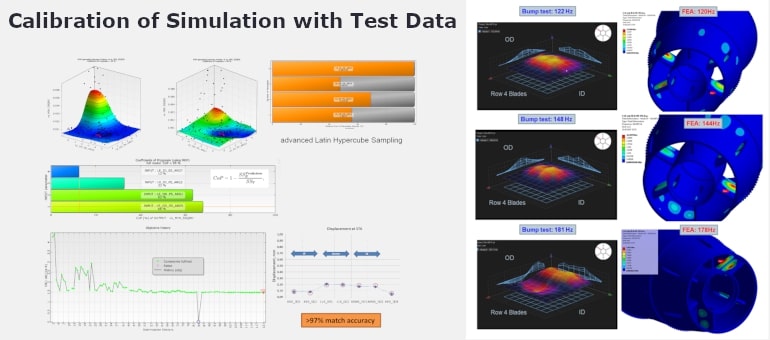

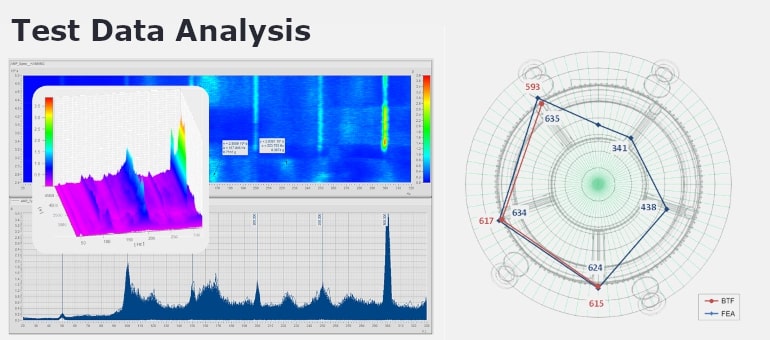

Design Optimization and Parameter Identification (Calibration)

Supports identification of optimal design parameters using automated and adaptive optimization workflows. Based on prior sensitivity analysis, the most influential parameters are selected for pre-optimization using response surfaces or metamodels. Wizard-driven algorithms — including gradient-based methods, evolutionary strategies, and custom approaches — guide the selection of optimal configurations across multiple objectives.

Example: Parameter identification and optimization of a turbine exhaust module — calibrating material properties and boundary conditions to match thermal behavior observed in test data.

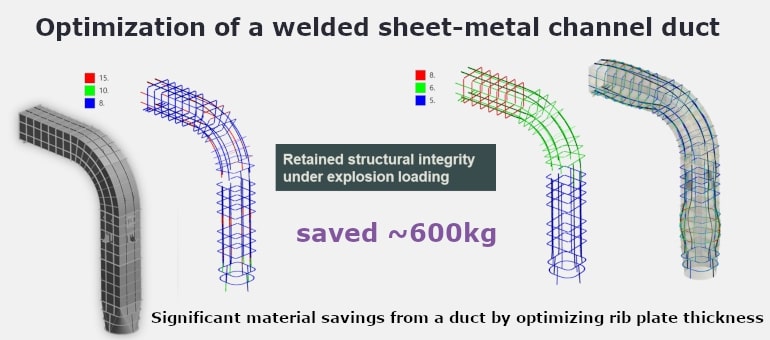

Weight and Performance Trade-off Analysis

Enables design decisions that balance structural durability, material efficiency, and production cost. Simulations are used to evaluate how changes in geometry, material thickness, or reinforcement layout affect strength, stiffness, and weight. This approach is especially valuable for welded constructions where weight reduction must not compromise performance under dynamic or pressure loads.

Example: Optimization of a welded sheet-metal channel duct — reducing rib thickness while maintaining explosion pressure resistance, leading to material savings without loss of structural integrity.

Robustness Evaluation

Quantifies the impact of variability and uncertainty in design parameters, manufacturing tolerances, and environmental conditions on product performance. Robustness analysis identifies the most critical scattering variables and applies algorithm-driven workflows to assess reliability and performance consistency.

Examples: Robustness analysis of a turbine exhaust casing — evaluating the influence of wall thickness deviations and boundary condition uncertainties on thermal stress margins.