CFD-Simulations

Fluid flow behavior and thermal-fluid interactions are evaluated using advanced CFD techniques to enhance performance, durability, and safety. Capabilities include steady and unsteady simulations, modeling of multiphase flows (VOF, Eulerian, and DPM), conjugate heat transfer (CHT), and turbulence-resolving approaches. Applicable across industries and flow regimes — from internal cooling passages and ducting to external aerodynamics and flows with entrained solids or droplets. The methodology provides detailed insight into heat transfer, pressure losses, phase interactions, and transient effects.

Key Capabilities

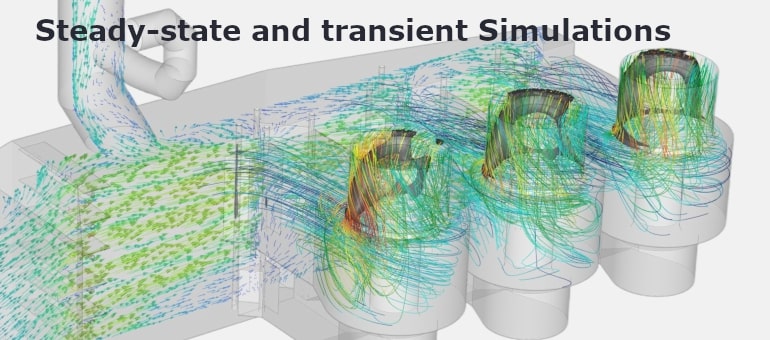

- Steady-state and transient simulations

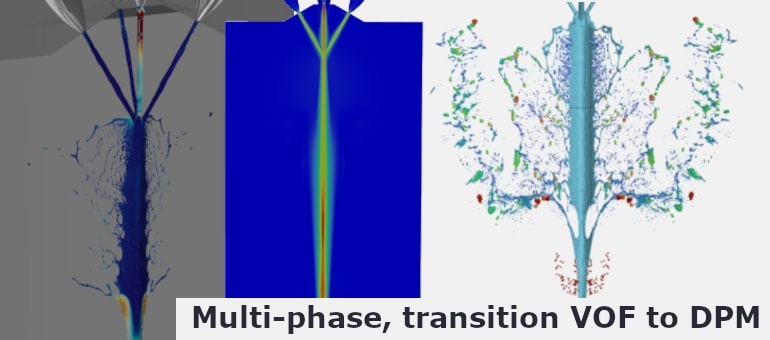

- Multiphase modeling — free surface, dispersed phase, and particle tracking for gas-liquid, solid-liquid, or spray flows (VOF, DPM, Eulerian)

- Turbulence modeling — for a wide range of flow regimes, from steady industrial flows to complex unsteady vortices

- Erosion, deposition, and particle tracking

- Conjugate Heat Transfer (CHT) — coupling of fluid and solid temperature fields

- Fluid-Structure Interaction (FSI) — simulation of flow-induced forces and structural deformation

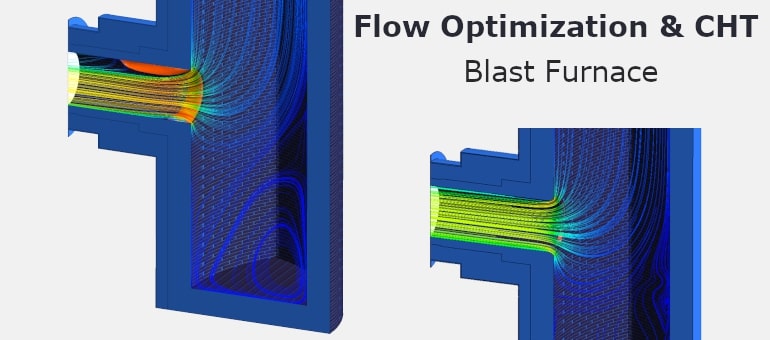

- Flow Optimization — reduction of pressure losses, enhancement of cooling efficiency, and performance-driven design refinement

More information

Steady-State & Transient Flow

Evaluates flow behavior under constant or time-varying conditions to capture pressure losses, recirculation, heat transfer, and temporal evolution of the fluid domain.

Example: Pressure and velocity field analysis in an exhaust diverter damper across multiple load conditions.

Erosion, Deposition & Particle Tracking

Tracks solid particles in a fluid domain to evaluate erosion hotspots, deposition zones, or carryover rates.

Examples: Sand particle erosion assessment of a control valve downstream of a gas compressor.

Turbulence Modeling

Resolves or models turbulence effects across a wide range of flow conditions — from smooth duct flows to separated or swirling structures.

Example: Swirling flow development in an exhaust diffuser and its impact on downstream pressure distribution.

Multiphase Flow (Free Surface, Dispersed, Spray)

Simulates interaction between immiscible fluids or between fluids and particles/droplets to capture interface motion, phase distribution, and separation effects.

Examples: Mixing of fuel, oxidant, and air in a combustion chamber to study injection behavior over an impingement plate, simulated using the Volume of Fluid (VOF) method with transition to a Discrete Phase Model (DPM). The analysis captures liquid sheet formation and its subsequent thinning and breakup.

Conjugate Heat Transfer (CHT)

Couples solid and fluid domains to simulate temperature distributions and heat fluxes under conductive and convective loading.

Example: Cooling performance analysis of an internally cooled turbine exhaust casing during peak thermal load.

Fluid-Solid Interaction (FSI)

Couples fluid dynamics and structural deformation to assess pressure-induced or thermally driven loading and the resulting structural response in real-time. Especially relevant where fluid forces and structural deflection interact dynamically.

Examples:

- Forced Response Analysis: Structural stress evaluation of a diverter damper blade under time-varying aerodynamic loads from unsteady CFD. Pressure fields are mapped — after FFT processing — to the structure to assess vibratory stresses and fatigue risk.

- Quasi-Static Stress Evaluation: Strength verification of a damper blade under peak pressure distribution extracted from steady-state CFD during full-load operation. Used to assess maximum stress and deformation without accounting for time-dependent effects.