Full-Scope Mechanical Integrity Support for Vane Cast Part Release

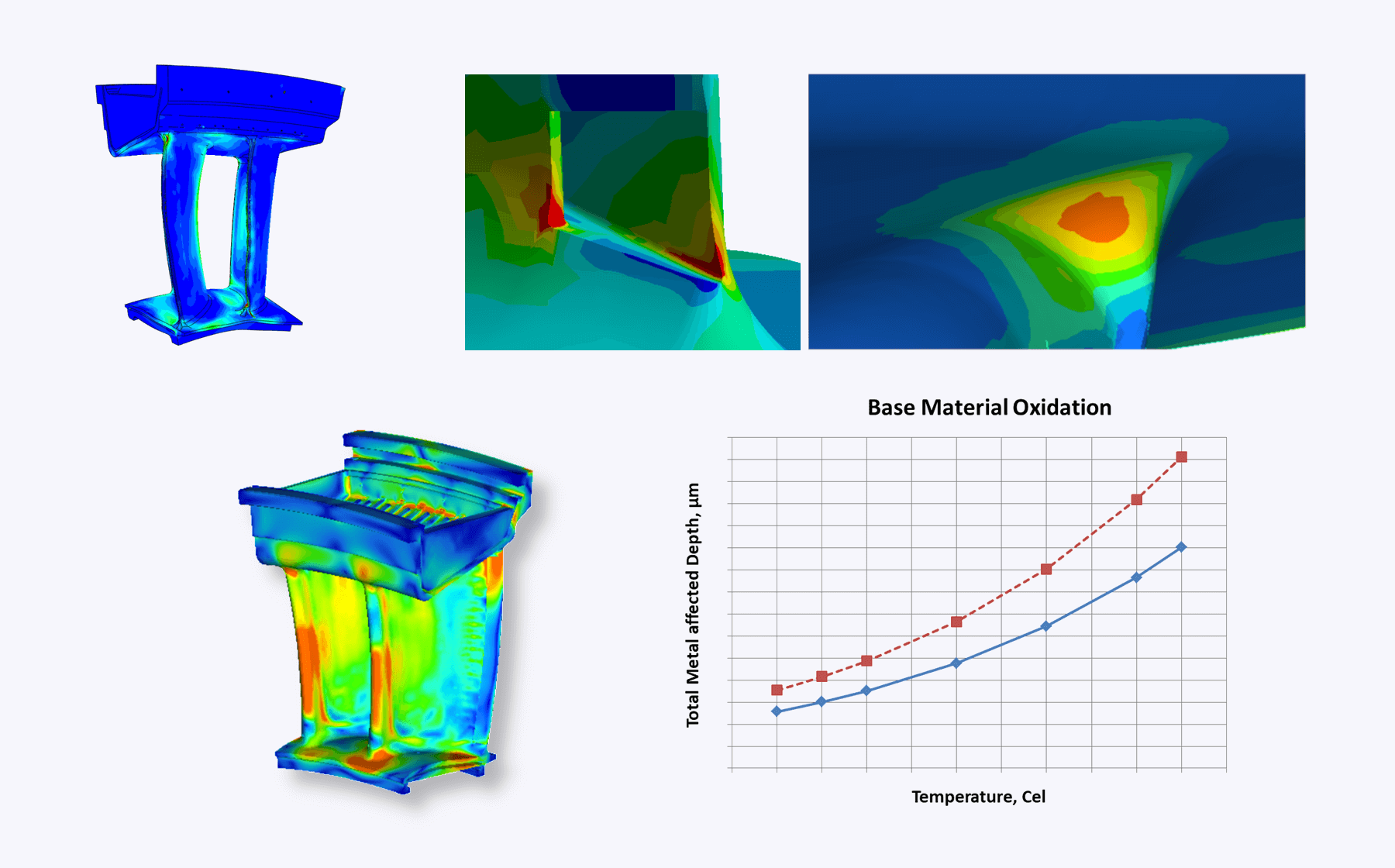

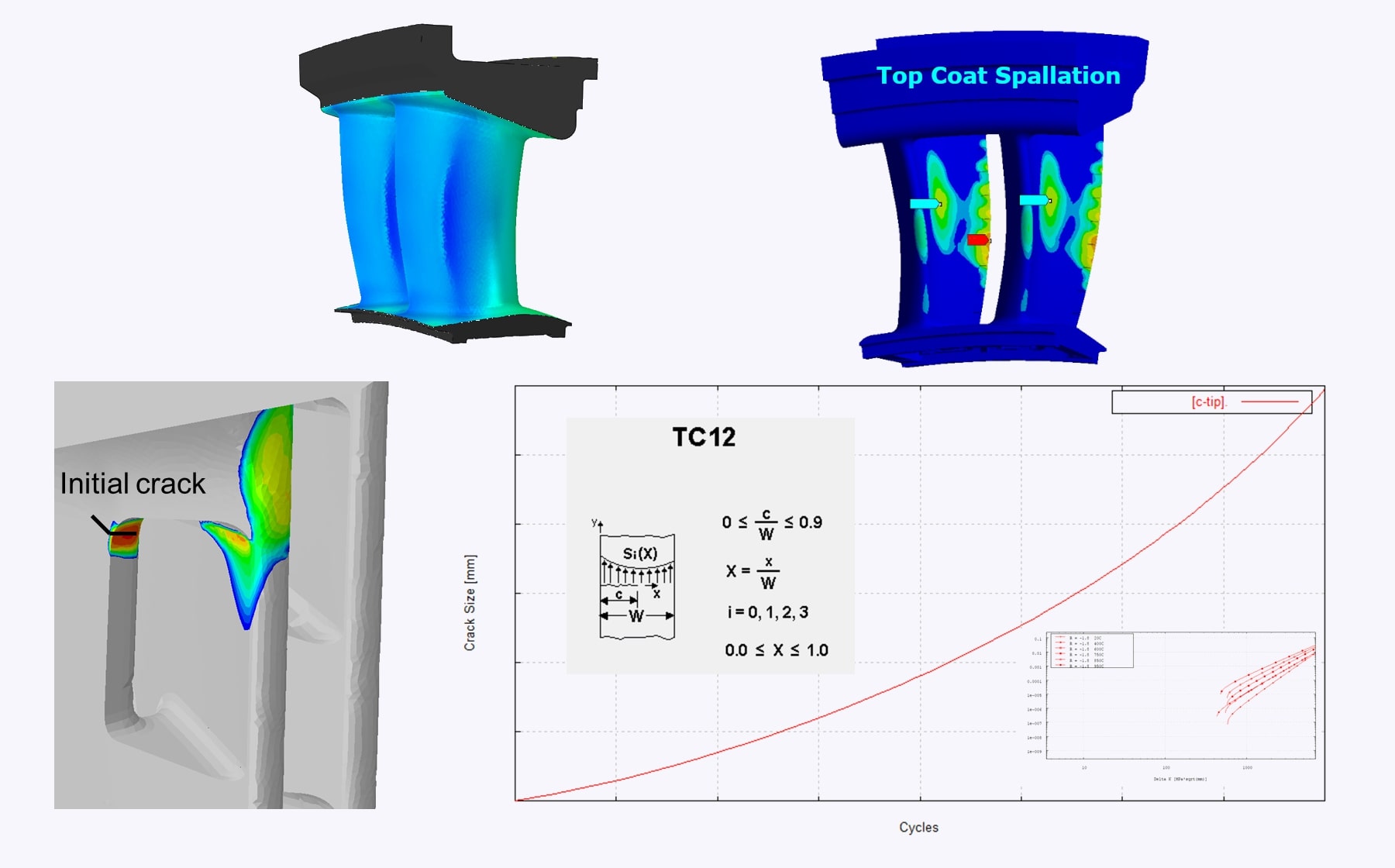

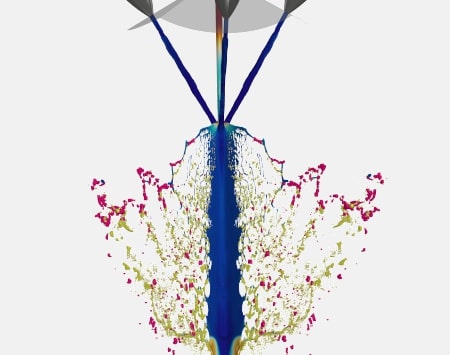

Comprehensive simulation support from concept selection to cast part release. Comparative thermo-mechanical analyses were performed for multiple design variants, including TMF, creep, and fracture mechanics. Material selection and coating behavior were evaluated through TBC spallation and BC depletion assessments. Mesh morphing was applied to support geometry optimization studies. Full-care assistance was provided throughout development reviews.

- Concept phase – Comparative analyses for three design concepts plus baseline (thermo-mechanical FEA, TMF, creep, etc.)

- Mechanical Integrity analysis support for concept selection and approval

- Design phase – Cast part release – Comprehensive analyses (thermo-mechanical FEA, TMF, creep, oxidation, fracture mechanics, etc.)

- Material selection and coating evaluation – Including TBC spallation and BC depletion analyses

- Mesh morphing for geometry optimization – Wall thickness optimization and cutback configuration studies

- Full-care assistance – Preparation of review documentation, participation in design reviews, and support in closing post-review action items

- Tools used: Hyperworks, Abaqus, Ansys, Franc3D, NASGRO