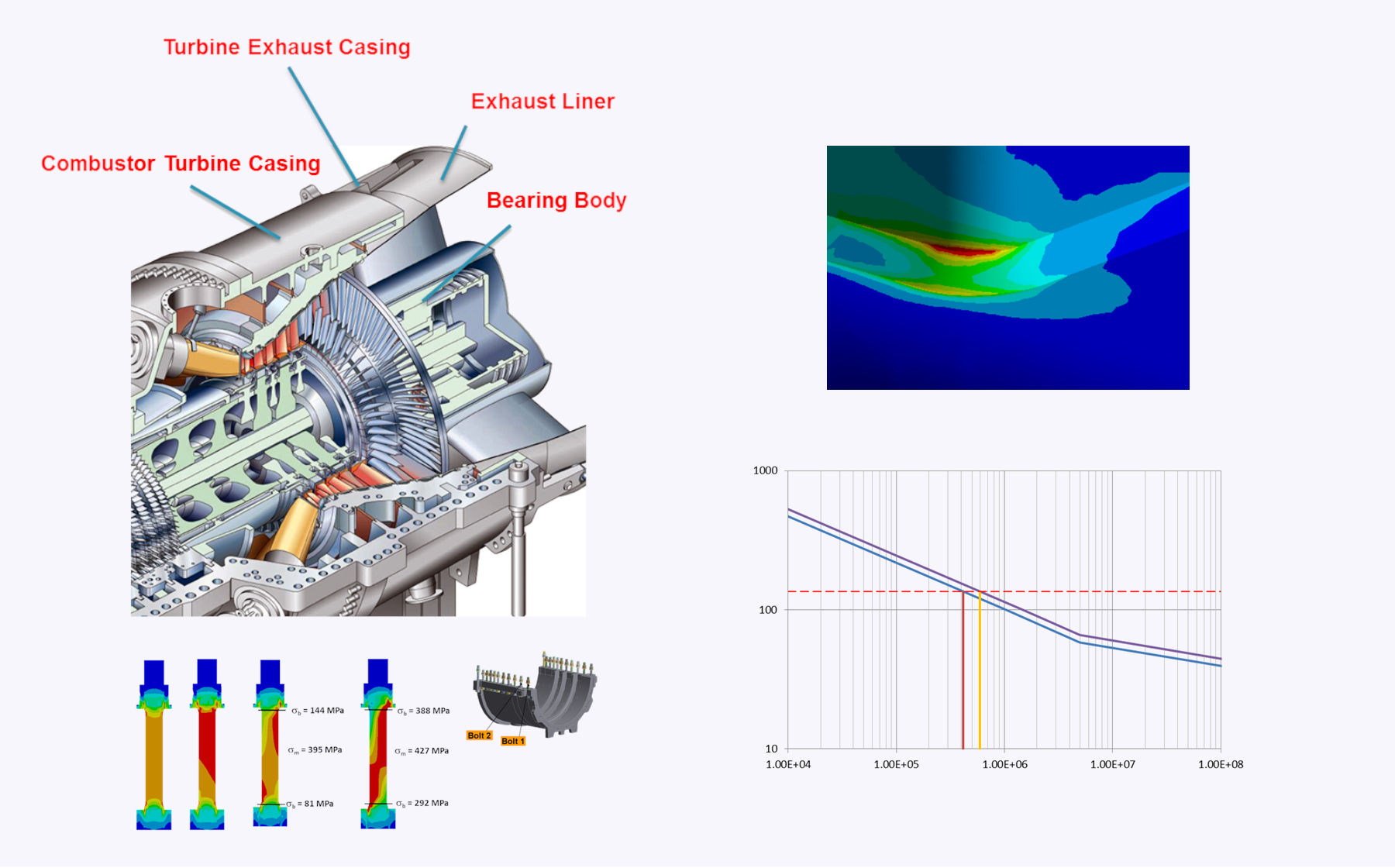

Comprehensive Simulation and Test Support for Exhaust Module Development

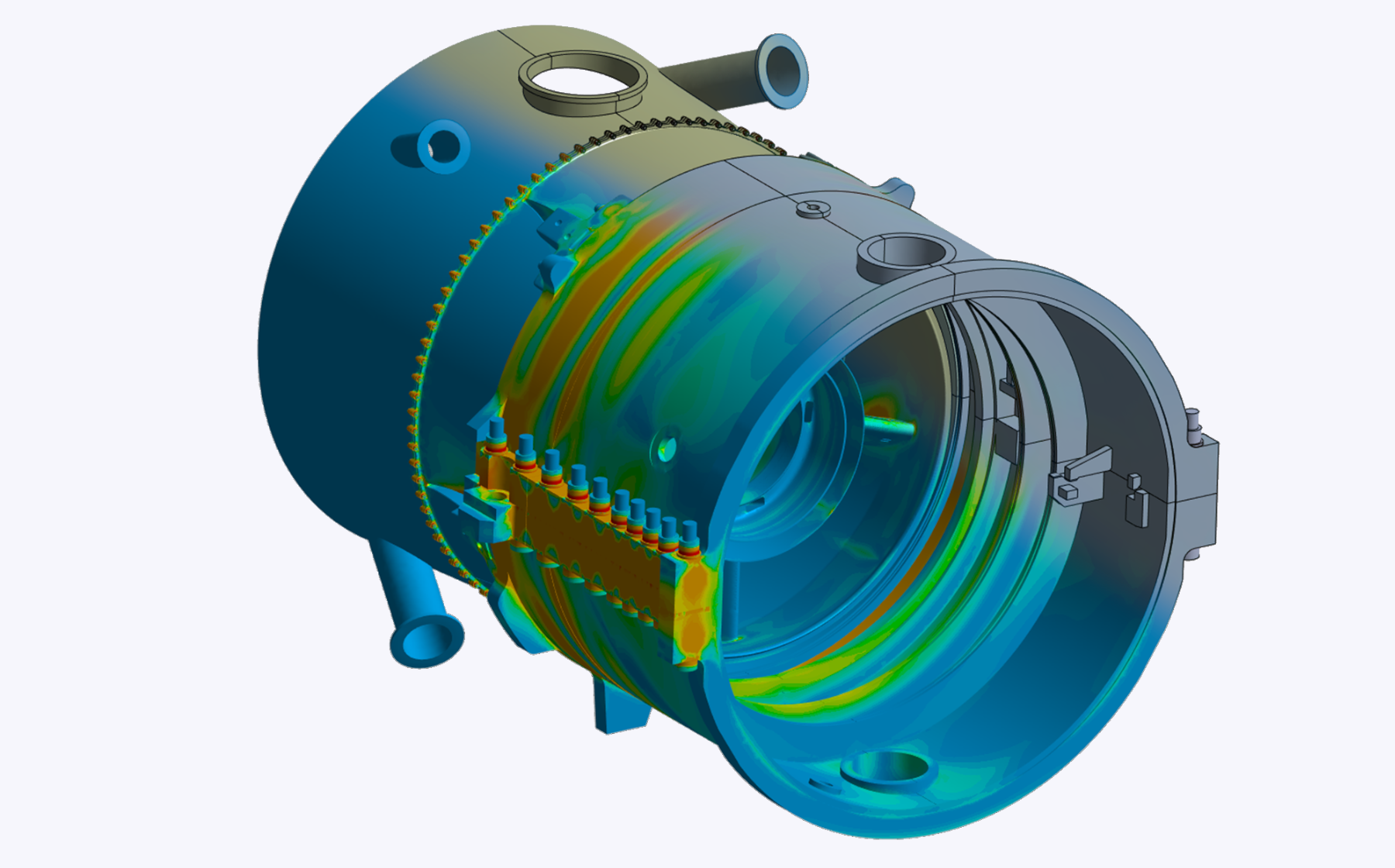

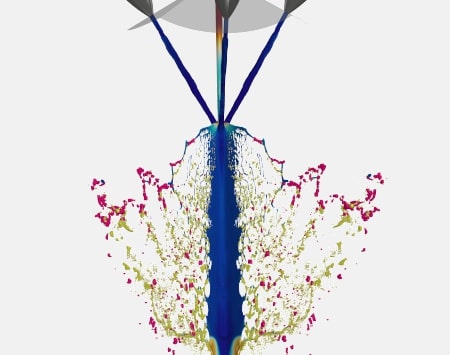

Simulation- and test-based support throughout all development phases of the exhaust module — from concept validation to release for casting, fabrication, and assembly. Key focus areas included structural integrity, fatigue, creep, fracture mechanics, leakage, and deformation behavior. Additional support included prototype test data evaluation, boundary condition calibration, and full participation in review processes, including documentation and closure of action items.

- Concept Phase Analyses – Feasibility evaluation and structural integrity checks

- Cast Part Release Support – Heat transfer, fatigue, structural integrity, bolted joints, and leakage assessments

- Fabrication Release Support – Fatigue, creep, and fracture mechanics evaluations

- Assembly Release Support – Deformation analysis and centering verification

- Full-Care Assistance – Preparation of review documentation, participation in design reviews, and support in closing post-review action items

- Post-Processing of Prototype Test Data

- Calibration of Boundary Conditions using Test Data