Mechanical Integrity Assessment of Baseline and Service Designs for Vanes and Ring Segments

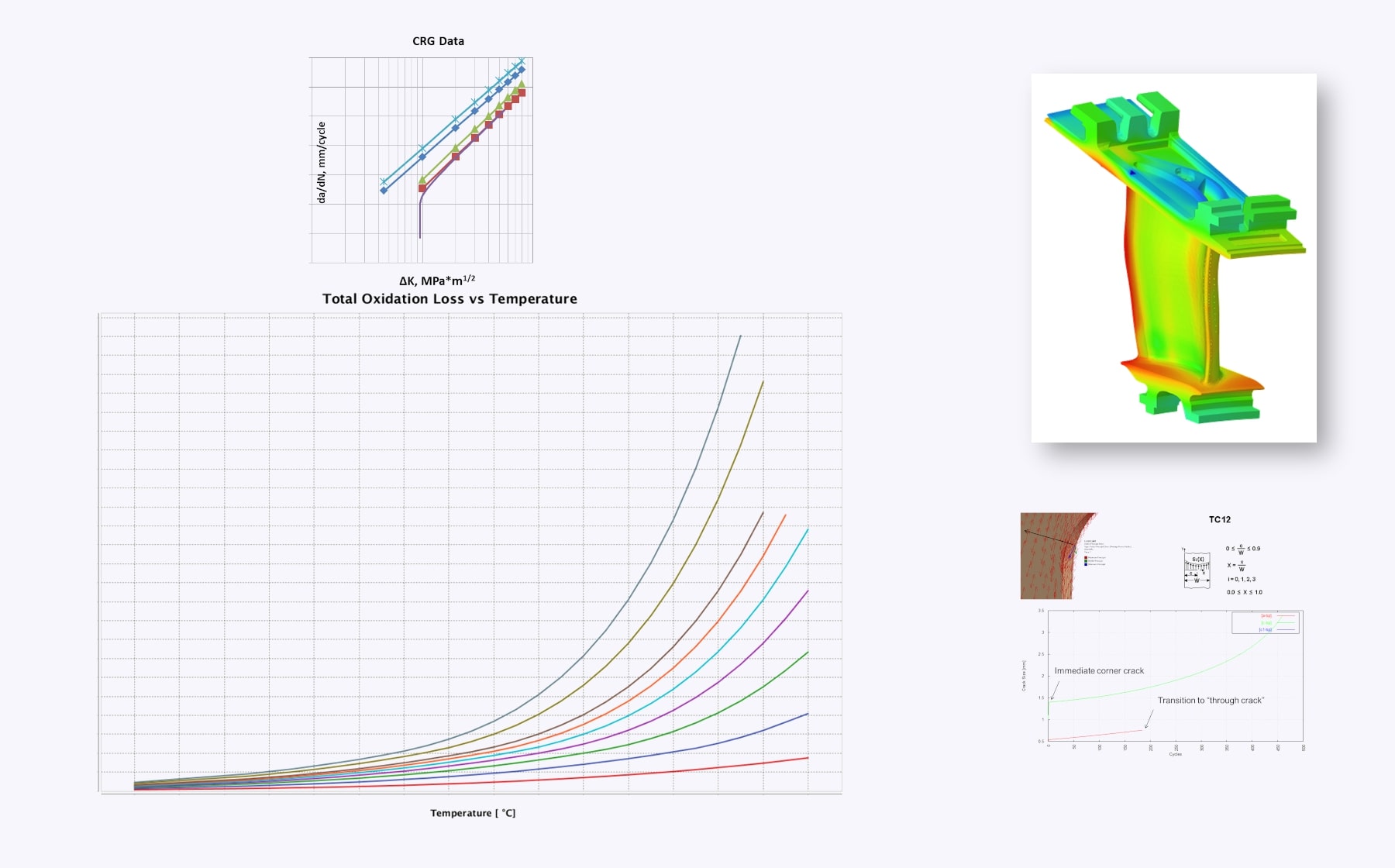

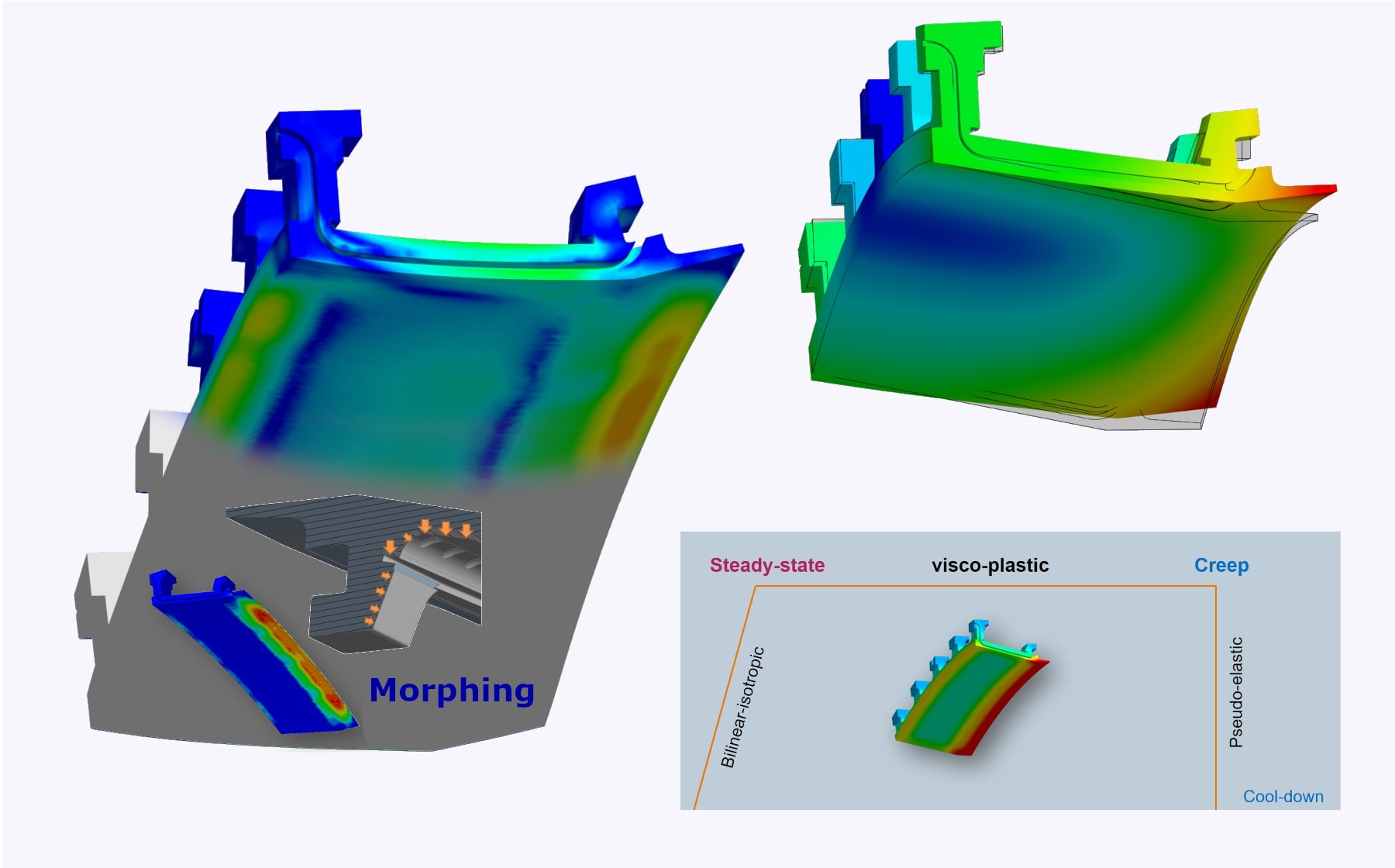

A comprehensive MI assessment was performed to investigate the thermal and mechanical behavior of baseline and service variants of vanes and ring segments under long-term operating conditions. The scope included fatigue and fracture mechanics evaluations, creep analysis, and oxidation resistance assessments. Particular focus was placed on the influence of TBC and abradable coating thicknesses, as well as degradation mechanisms such as spallation and bond coat depletion. Advanced techniques, including mesh morphing in Hypermesh, were employed to enable efficient evaluation and direct comparison between design configurations.

- Comparative thermal & structural analyses for Baseline and Modification

- Creep analysis performed for long-term thermal exposure with abradable coating

- Bond Coat (BC) depletion analysis considering diffusion limits on both hot and cold sides

- Thermal Barrier Coating (TBC) spallation assessment based on operating temperatures and coating thickness

- Base material oxidation assessment — under long-term exposure at elevated temperatures

- Low Cycle Fatigue (LCF) and Thermo-Mechanical Fatigue (TMF) analyses — for configurations with varying TBC and abradable layer thicknesses

- Fracture Mechanics evaluation at critical LCF location using both conservative and less conservative methods (IWM VERB and NASGRO)

- Analyses performed in Abaqus and Hypermesh