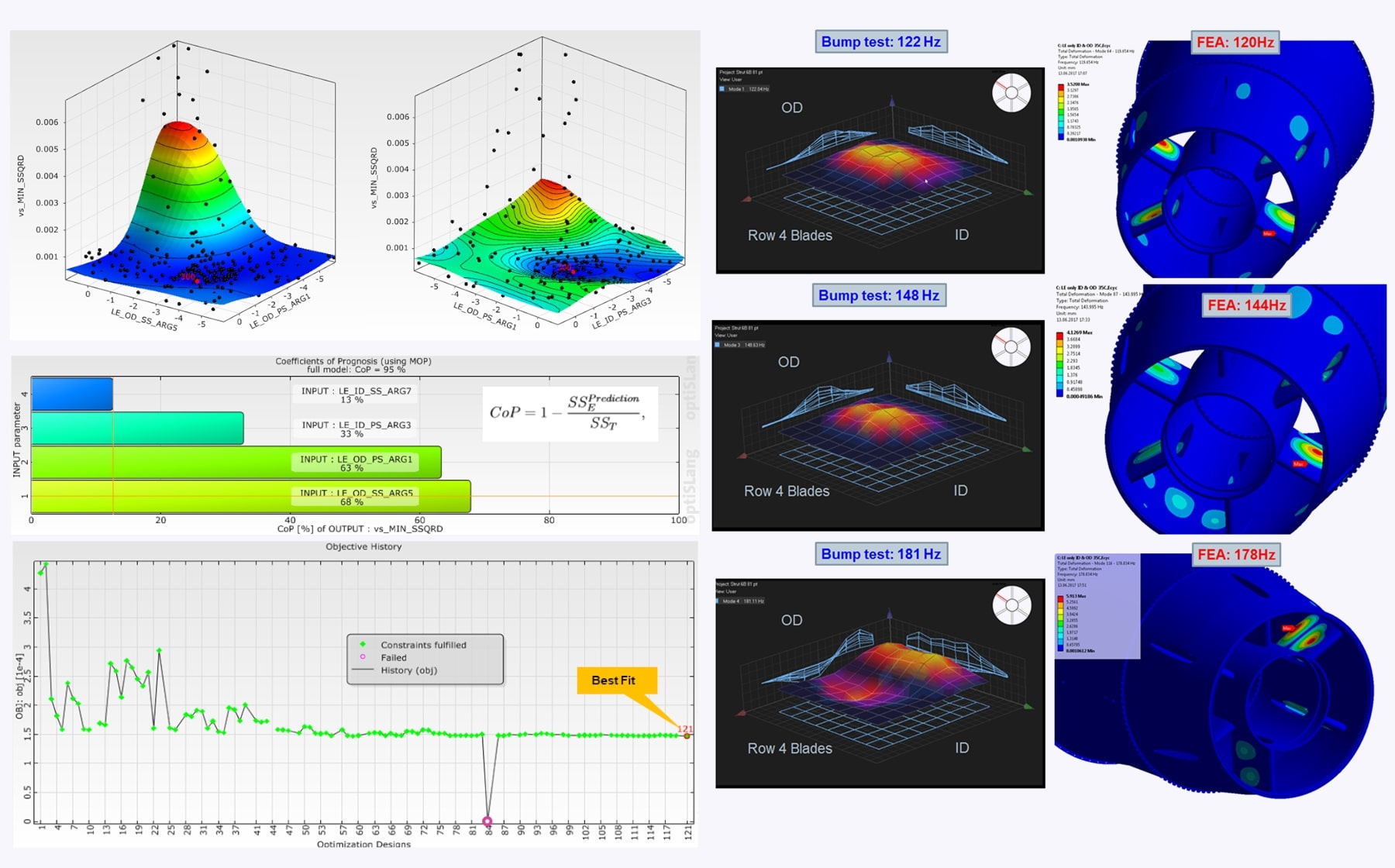

Calibration of the natural frequencies of an exhaust liner strut shield was performed using prototype measurement data. The goal was to adjust the simulation model to accurately reproduce the observed vibration behavior in harmonic response analysis. Contact stiffnesses at multiple locations were calibrated using accelerometer signals, followed by meta-model optimization and high-cycle fatigue (HCF) evaluation based on the calibrated results.

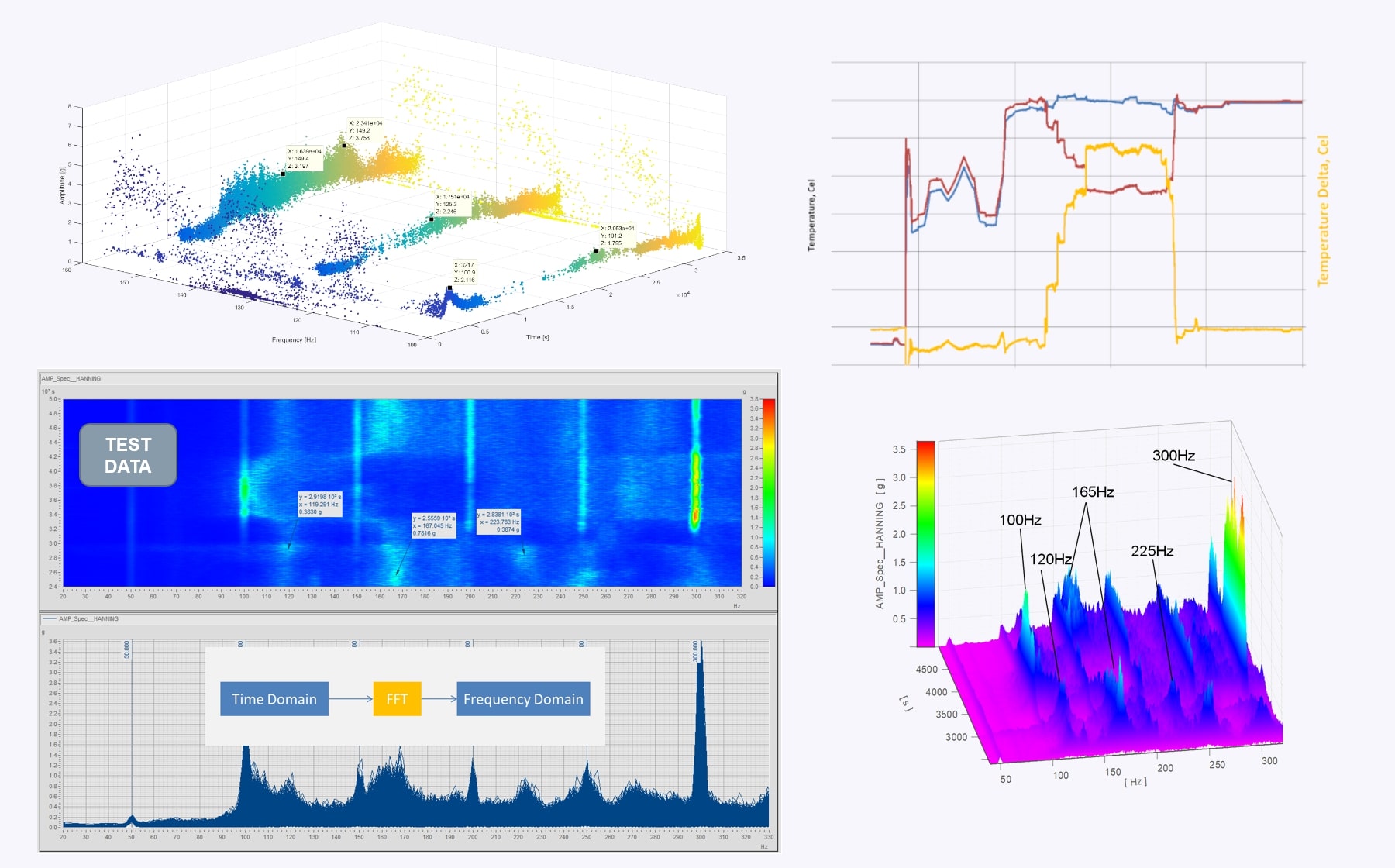

Vibration measurements were post-processed under multiple engine operating conditions to assess structural stress levels and identify potential resonance risks. FFT analysis and waterfall diagrams were used to interpret acceleration signals across the relevant frequency spectrum. A calibrated modal finite element analysis was conducted to estimate stress responses under critical excitation amplitudes.

- Post-processing and FFT-based evaluation of experimental vibration data

- Visualization of excitation spectra using waterfall diagrams

- Identification of dominant frequency peaks and vibration amplitudes across the full spectrum

- Assessment of vibration amplitudes and mean stress levels during different operating modes

- Calibration of 8 independent contact stiffnesses using 7 accelerometers on a strut shield

- Verification of natural modes and frequencies via BUMP test

- Calibrated modal and harmonic response analyses

- Estimation of stress amplitudes and HCF assessment